INDUSTRY DIGITALIZATION WITH JAHAANN

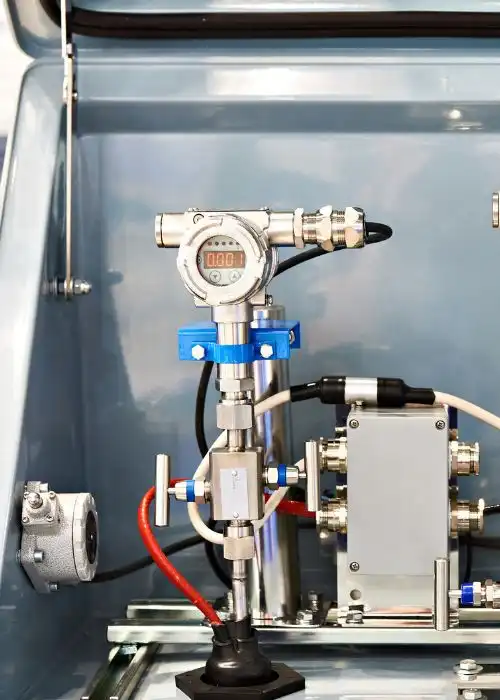

Jahaann offers integration of sensors and equipment to create efficient and automated systems for businesses. With their expertise, Jahaann can design custom solutions to integrate sensors and equipment, facilitating real-time monitoring and analysis of critical data points. They work with various industries to optimize their operations and improve efficiency using cutting-edge technologies. By integrating sensors and equipment, Jahaann helps businesses to streamline their processes, reduce downtime, and save costs.

OUR INSTALLATION AND COMMISSIONING SERVICES INCLUDE THE FOLLOWING:

- Physical installation of instruments, including assembling, connecting and configuring the instruments.

- Calibration of instruments to ensure accurate measurement.

- Functional and performance testing to ensure that the instruments are operating within specified parameters

- Integration and communication with other systems, such as SCADA and PLC.

- Troubleshoot and resolving any issues or problems that are identified during commissioning.

- Provide training and support to the customer’s personnel.

Transform Your Plant Operations with Our Jahaann Services

Frequently Asked Questions

FAQs about Jahaann

What is Integration of Sensors & Equipment’s ?

Integrating sensors and equipment is the process of connecting sensors and equipment to a central control system. This allows the operator to monitor and control the sensor data and equipment remotely. This integration enables the seamless exchange of information between various components of a system, leading to enhanced efficiency, improved safety, and optimized operations.

What are Benefits of Integration of Sensors & Equipment ?

- Increased Efficiency: By integrating sensors and equipment, real-time data can be collected and analyzed, enabling operators to make informed decisions that optimize processes and minimize downtime.

- Reduced Costs: Predictive maintenance can be implemented by monitoring sensor data, allowing for proactive identification and resolution of potential issues before they lead to costly breakdowns.

- Improved Safety: Integrated systems can detect and alert operators to potential safety hazards, preventing accidents and ensuring a safer work environment.

- Enhanced Data Collection and Analysis: Integrated systems provide a centralized platform for collecting and analyzing data from various sources, enabling comprehensive insights and data-driven decision-making.

- Increased Productivity: By optimizing processes and reducing downtime, integrated systems contribute to increased productivity and overall operational efficiency.

Common Applications for Integration of Sensors & Equipment ?

- Manufacturing: Sensor integration enables automation, process control, and quality monitoring in manufacturing plants.

- Logistics: Sensor-equipped vehicles and warehouses facilitate real-time tracking, inventory management, and route optimization.

- Building Automation: Integrated sensors optimize HVAC, lighting, and security systems for energy efficiency and occupant comfort.

- Oil and Gas: Sensor data is crucial for monitoring pressure, temperature, and flow rates in oil and gas operations.

- Utilities: Integrated sensor networks enable smart grid management, leak detection, and predictive maintenance in utilities.

- Healthcare: Sensor-equipped devices provide real-time patient monitoring, vital signs tracking, and medication administration support.

- Agriculture: Sensor data guides irrigation systems, optimizes fertilizer application, and monitors crop health in precision agriculture.

- Environmental Monitoring: Sensor networks track air quality, water quality, and environmental conditions for monitoring and compliance purposes.