Industrial Automation

Elevating Automation Excellence

Explore the forefront of automation excellence through our state-of-the-art solutions. Simplify intricate processes, curtail ownership costs, and enhance safety measures with our advanced system infrastructure.

Industrial Automation Project - Siemens PLC Migration

Successfully migrated Siemens S5 PLC to S7 PLC for UHT-03 , including installation and commissioning of 90 I/Os in the new Wago Extreme Series PLC (750-8202/040-000). Led team in cable organization, tagged remaining cables, and executed new control programming, modifying logic to align with UHT process requirements.

HMI Upgrade: Beijer to WinCC flexible 2008 for Pasteurization Plant

Executed seamless migration of Beijer HMI to WinCC flexible 2008, featuring a bespoke interface crafted to meet client requirements, elevating control and monitoring capabilities within the Pasteurization Plant.

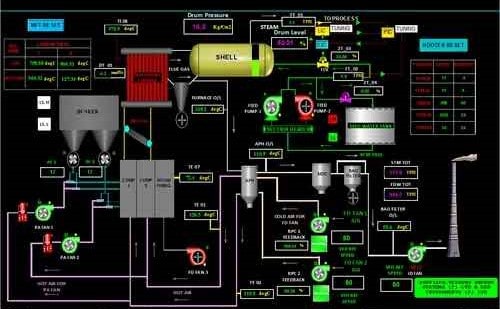

Energy System Upgrade: Schneider Integration & Redundant Logic

Modified and integrated energy analyzers, flow meters in Schneider Vijeo Citect. Designed shutdown logic for Schneider Quantum series Redundant system and incorporated breaker statuses into SCADA for seamless monitoring.

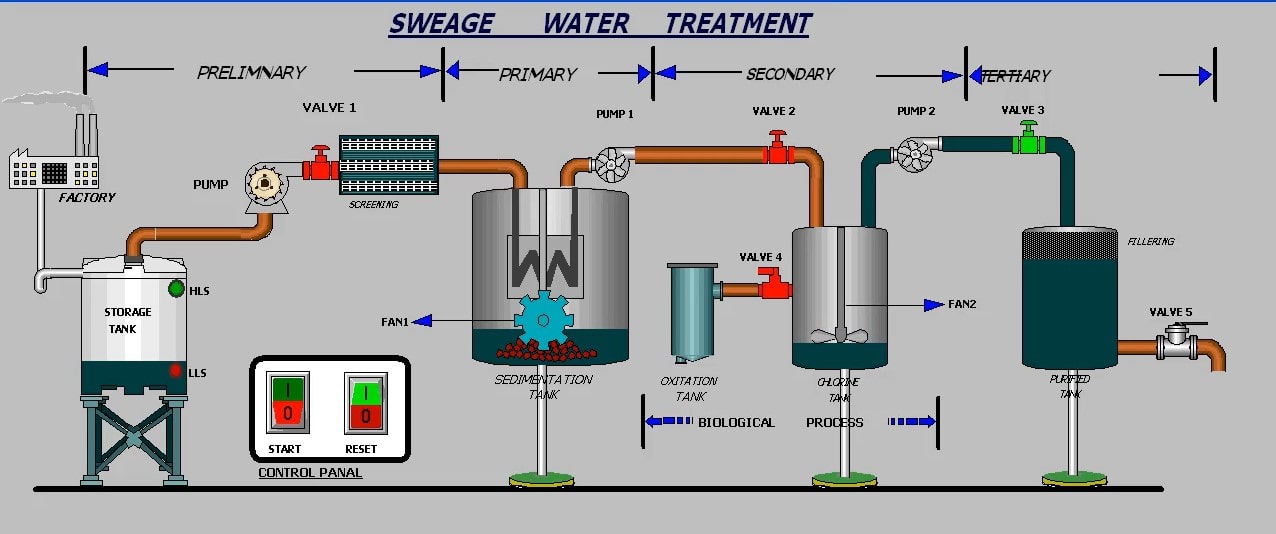

Efficient Wastewater Treatment Automation

Revolutionizing wastewater treatment through meticulous PLC S7-1200 programming and innovative HMI TP-1200 design. Our comprehensive automation solution optimizes processes for enhanced efficiency and environmental sustainability.

EMS Enhancement & PLC Integration

Successfully modified and integrated 47 energy analyzers and flow meters into the Running EMS using Schneider Vijeo Citect 7.4. Additionally, designed shutdown logic in Schneider Twido soft PLC and installed Wago PLC in LT-06 to develop shutdown logic, showcasing expertise in seamless system enhancements and PLC integrations.

Chiller Pump Control System Optimization

Successfully commissioned the pump control system in the Chiller area, implementing logic design for MCU control through Wago PLC. Our expertise extends to tailored HMI designing aligned with client-provided layouts, ensuring optimal functionality and efficiency in the Chiller Pump Control system.

Schneider Energy Monitoring: 329-Device Commissioning

Commissioned 329 devices in PME 2021, configuring energy analyzers, flow meters, and TCU. Installed gateway modules, laid Modbus cable daisy chain, and performed PME software setup. Implemented dashboard design, trend analysis, single-line diagram creation, and robust communication loss and over/under current/voltage alarms, enhancing operational monitoring capabilities.

Auto Filler Pump Control System Optimization

Successfully commissioned the pump control system for the Auto Filler, integrating Wago PLC to control various product supply pumps. Achieved seamless signal integration in Wago from the BNR PLC installed at the Serac Auto Filler, enhancing overall control and efficiency in the Filler Pump system

SCADA System Upgrades: Aveva 2020 R2 Integration

Successfully migrated SCADA systems from Wonderware InTouch SCADA 2017 R1 to Aveva 2020 R2 System Platform, with Siemens S7 1200 PLC. Upgraded another system from Wonderware InTouch SCADA 2014 R2 to Aveva 2020 R2 with Allen Bradley Compact Logix 5370 PLC, and a third from Wonderware InTouch SCADA 2017 to Aveva 2020 R2 with Omron Sysmac CP1H PLC. These transitions ensure enhanced functionality and compatibility in each respective automation environment

Industrial OT Cybersecurity Framework

Developed an OT Cybersecurity framework comprising plant architecture layout based on distinct levels, conducted comprehensive risk assessments, and executed gap analyses. Our approach ensures robust protection, identifying vulnerabilities and fortifying your industrial systems against potential cyber threats