INDUSTRY DIGITALIZATION WITH JAHAANN

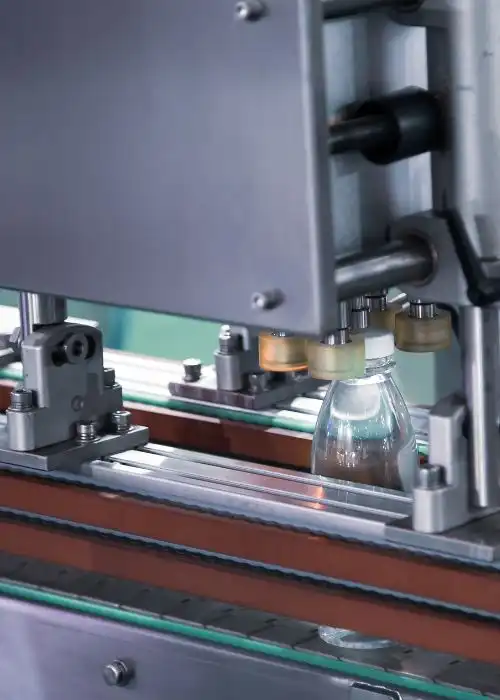

“Jahaann” provides liquid monitoring services that help businesses to track and manage the levels of liquids in their facilities. This service can include the installation of sensors or other monitoring devices, as well as the development of custom software solutions to track and analyze liquid levels. By monitoring liquid levels, businesses can avoid spills, leaks, or overflows that can cause damage or result in downtime. This helps to ensure that operations run smoothly and safely, while also reducing costs associated with spills or leaks. Overall, “Jahaann’s” liquid monitoring services are a valuable tool for businesses looking to optimize their operations and ensure the safe handling of liquids.

OUR LIQUID MONITORING SERVICES INCLUDE THE FOLLOWING:

- Real-time data: The liquid monitoring dashboard provides real-time data on liquid levels, allowing users to quickly identify potential issues and take immediate action.

- Customizable views: The dashboard is customizable, allowing users to choose the data they want to see and how it is presented.

- Alert notifications: The dashboard can be configured to send alert notifications when liquid levels reach a certain threshold, ensuring that users are always informed of potential issues.

- Historical data: The dashboard provides access to historical data, allowing users to track trends and identify areas for improvement.

- Multiple device support: The dashboard is designed to support multiple devices, allowing users to monitor liquid levels from anywhere at any time.

Forecasting: The dashboard can provide forecasting for future liquid levels based on historical data and trends.

Transform Your Plant Operations with Our Jahaann Services

Frequently Asked Questions

FAQs about Jahaann

What is liquid monitoring?

Liquid monitoring is the process of measuring and tracking the level, flow rate, and quality of liquids. This information can be used to optimize processes, prevent spills, and ensure compliance with regulations.

What are the benefits of liquid monitoring?

- Improved process efficiency

- Reduced costs

- Enhanced safety

- Increased compliance with regulations

- Reduced environmental impact

What industries use liquid monitoring?

- Water and wastewater treatment

- Oil and gas

- Chemicals

- Manufacturing

- Food and beverage

What are some of the challenges of liquid monitoring?

- Accuracy: Ensuring that the liquid monitoring system is accurate can be difficult, especially for liquids with high viscosity or solids content.

- Reliability: Liquid monitoring systems can be sensitive to environmental factors, such as temperature and humidity.

- Maintenance: Liquid monitoring systems require regular maintenance to ensure that they are functioning properly.